Technical

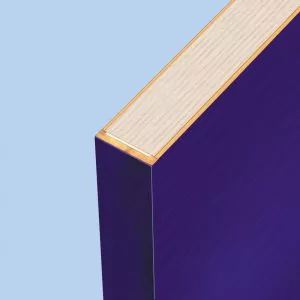

Palusol®SW is a ready made laminated board material that can be used to manufacture both flat and raised and fielded – fire resisting panelled doors.

In a joint development between Mann McGowan® and BASF SE, fire resistance tests have been successfully conducted on both 30 and 60 minute door constructions.

These tests carried out by Chiltern International Fire in accordance with BS 476 Part 22: 1987 have culminated in two global assessments Chiltern

A0 9136 and A0 9165.

Our Technical Manual is available to download here and provides details of all of the products required to manufacture and install FD30 and FD60 fire resisting panelled doors.

The Palusol®SW Boards and all the intumescent materials should be obtained direct from Mann McGowan to ensure the fire test evidence is complied with.

We cannot supply SW Panels in isolation, all components must be supplied together.

Benefits

By using Palusol®SW boards manufactured by BASF SE and distributed by Mann McGowan®, specialist joinery producers and OEM’s can manufacture flat and raised and fielded panelled fire resisting door-sets. As the boards are pre-manufactured and pressed, this provides savings on production time and negates the need for R&D on the part of the manufacturer.

These tangible benefits equates to lower production costs as well as allowing the producer to tender for work in this increasing market sector.

Other benefits include;

- Global Fire Assessments from Chiltern International Fire

- 10mm thick panels can be used on FD30 and FD30(S) constructions

- A double layer of 10mm thick panels can be used on FD60 and FD60(S) constructions

- Customised raised and fielded decorative panels can be utilised

- Commercially available wood adhesives can be used

- Up to 10 panels per door leaf can be accommodated

- Glazing apertures can be incorporated

- Acoustically tested in accordance with BS EN ISO 10140-2: 2010

- Allows for the use of Softwood at minimum density of 510kg/m3

Quality Assurance

Mann McGowan and BASF SE are a quality assured companies in accordance with ISO 9001: 2015

BASF SE Implements and maintains an environmental system in accordance with ISO 14001: 2004

Palusol® SW4 Boards

Product Code:

Palusol®SW4

Standard Dimensions: 2160mm x 1110mm x 10mm*

Weight Per Sheet: 27kg per sheet

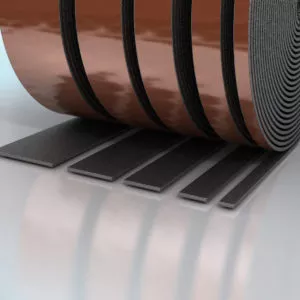

Cutting and Working

*The raw edges of the board should be trimmed 5mm all around.

Palusol®SW can be cut and processed using standard woodworking machinery. Carbide tipped cutting tools are recommended for longer usage.

Cut edges which arise during processing must be coated and adequately protected

Safety Precautions during Processing

Sodium silicate dust is created during the cutting, drilling or milling of Palusol®SW. It must not get into the eyes or respiratory passages and the use of appropriate extraction facilities and wearing of safety glasses and dust masks are strongly advised.

Storage and Transport

Palusol®SW should be protected from water, high atmospheric humidity and sustained temperatures above 40°C. The boards should be stored horizontally and supported over their entire area. Protective gloves should be worn.

Reviews

There are no reviews yet.